Enhancing Norther Offshore Wind Farm Performance with Marlinks' Cable Sensing Monitoring Solutions.

Challenge: Managing a vast and complex offshore wind farm in a harsh offshore environment.

Solution: Marlinks’ fiber optic sensing monitoring solutions enable real-time monitoring of critical components.

Results: The integration of Marlinks’ solutions at the Norther Offshore Wind Farm has introduced several key benefits: Real-time monitoring, enhanced safety, predictive maintenance, centralized cable insights and environmental impact reduction.

The Norther Offshore Wind Farm, located in the North Sea, Belgium, consists of 44 turbines with a combined capacity of 370 MW and generating the equivalent of the annual power consumption of approximately 400.000 households. To maximize its efficiency and safety, Norther has integrated state-of-the-art fiber optic sensing monitoring solutions from Marlinks, a global leader in the field. Marlinks’ solution spans integrating the necessary hardware, developing the requested software and providing the end client with a dashboard.

Challenge: Navigating Complexities in Offshore Wind Farm Management

Managing a vast and complex offshore wind farm in a harsh offshore environment poses numerous challenges, including understanding cable challenges and optimizing energy production.

Solution: Real-Time Monitoring for Offshore Wind Farm Success

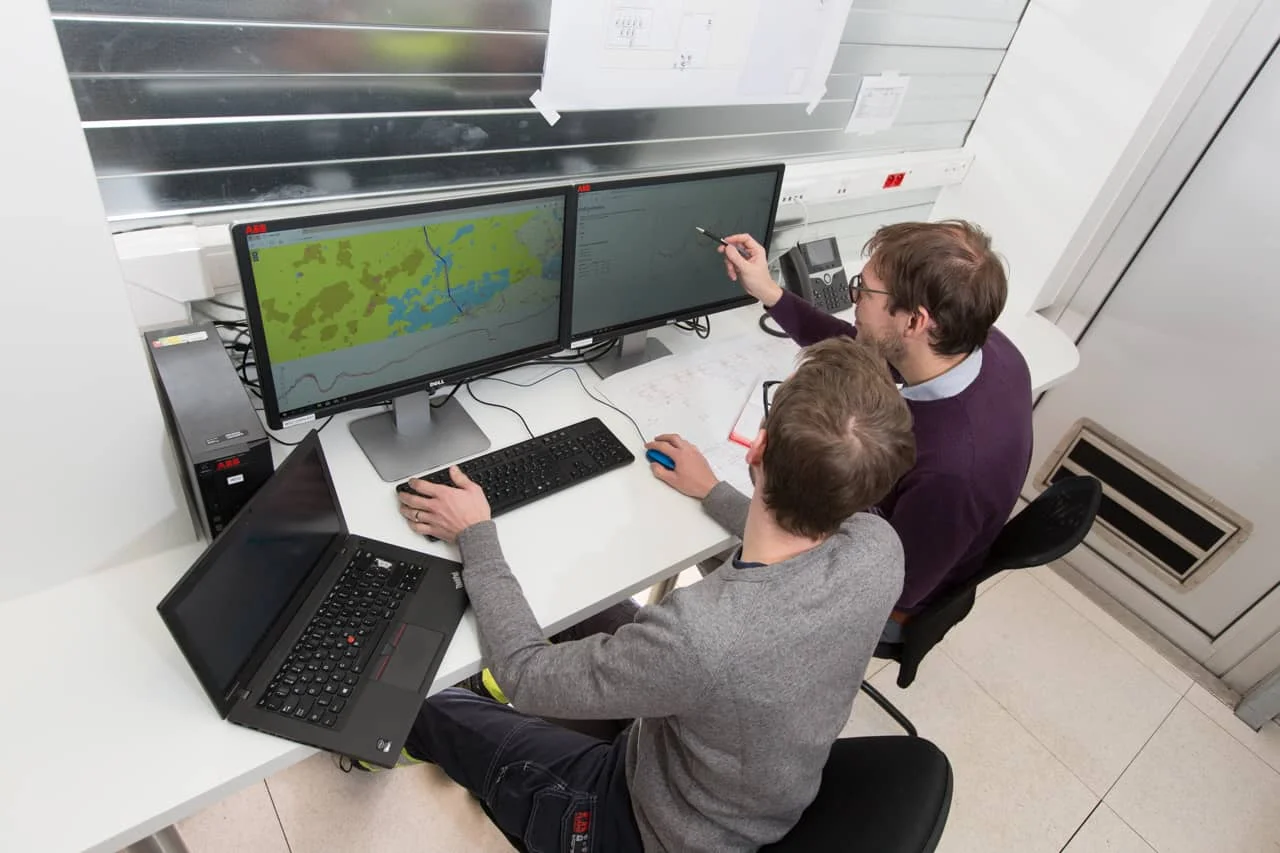

Marlinks’ fiber optic sensing monitoring solutions enable real-time monitoring of critical components such as power cables. The data collected through different cable monitoring devices can be used to identify and address potential issues promptly, minimizing downtime and costly repairs. Additionally, Marlinks’ technology helps detect and mitigate risks, such as cable damage or anchor movements, ensuring the energy production, safety of personnel and equipment.

Results: Transforming Offshore Wind Farm Operations with Marlinks' Solutions

The integration of Marlinks’ solutions at the Norther Offshore Wind Farm has introduced several key benefits:

- Real-time monitoring: Marlinks’ fiber optic sensing solutions enable real-time monitoring of critical components such as power cables and subsea structures. By continuously assessing conditions, any potential issues can be identified and addressed promptly, minimizing downtime and costly repairs.

- Enhanced safety: Safety is paramount in offshore wind farm operations. Marlinks’ technology helps detect and mitigate risks, such as cable damage or anchor movements, ensuring the safety of personnel and equipment.

- Predictive maintenance: By collecting extensive data on the performance of various assets, predictive maintenance becomes possible. This proactive approach reduces maintenance costs and extends the lifespan of essential equipment.

- Centralized cable insights: The integrated graphical user interface stands as a unified platform, providing a centralized and user-friendly access point for Norther to explore and utilize Marlinks’ complete suite of cable integrity monitoring solutions, streamlining the management and optimization of their cable infrastructure.

- Environmental impact reduction: The efficient operation of the Norther Offshore Wind Farm facilitated by, amongst others, Marlinks’ technology contributes to a significant reduction in carbon emissions, further supporting Belgium’s commitment to renewable energy.

Conclusion: Marlinks' Innovations Power a Sustainable Future at Norther Offshore Wind Farm

The integration of Marlinks’ fiber optic sensing monitoring solutions within the Norther Offshore Wind Farm has elevated its performance and sustainability. By enabling real-time monitoring, enhancing safety, promoting predictive maintenance, and increasing energy production, Marlinks’ technology has become an indispensable component in the success of this offshore wind farm. As the world looks to expand its renewable energy capacity, such collaborations between technology innovators and renewable energy pioneers pave the way for a brighter, more sustainable future.

More information?

Are you responsible for the health of submarine cables? Let’s have a chat at sales@marlinks.com and we will be happy to help you.

Source: www.norther.be and Bram De Baere (Deputy Technical Director – Norther)