The Relation Between Core and Fiber Temperatures of a 3P XLPE Cable.

Challenge: Understand the relationship between core (conductor) and fiber temperatures.

Solution: RC-ladder model based on finite-element (FEM) calculations.

Results: The comparison between measured core temperatures and those derived from the in-house developed RTTR model based on DTS temperature revealed the predictive power of the Marlinks RC-ladder model. The utilization of the FEM-based calculation proved to be a strong indicator for RTTR accuracy.

In the realm of submarine power cables, deciphering the intricate relationship between core (conductor) temperatures and fiber temperatures is of paramount importance. This understanding forms the bedrock of accurate real-time thermal rating (RTTR), enabling optimal performance and cost-effective cable selection. Discover how innovation, through Marlinks’ RC-Ladder Model and rigorous experimentation, has cracked the code of submarine cable temperatures, revolutionizing their performance and efficiency.

Challenge: Cracking the Code of Submarine Core and Fiber Temperatures

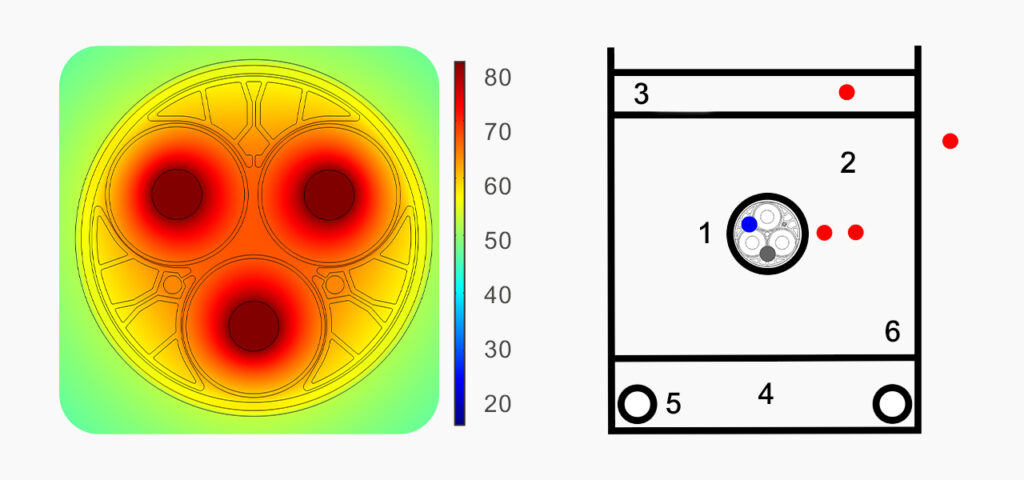

In the context of submarine power cables, understanding the relationship between core (conductor) temperatures and fiber temperatures is crucial for accurate real-time thermal rating (RTTR). This information enables optimized performance and cost-effective cable selection. However, accurately establishing this relation presents challenges due to the complex spacer geometry and the need to surpass industry-standard current limitations for heat generation.

Solution: Innovating with Marlinks' RC-Ladder Model and Rigorous Experimentation

Marlinks, a pioneering player in subsea cable monitoring technology, proposed a novel thermal RC-ladder model based on finite-element (FEM) calculations. To validate this model, an experimental setup was designed. A 20-meter-long 1800 mm², 1000A export cable was buried in a sand box. Fiber temperatures were monitored using a distributed temperature sensing (DTS) device, while core temperatures were measured using installed thermocouples. Current profiles were meticulously designed, including a 24-hour constant current and a synthetic dynamic load, with the latter involving a challenging 180% of the maximum allowed current.

Results: Empowering Submarine Power Cables for Elevated Performance

The experiment produced compelling results. The comparison between measured core temperatures and those derived from the in-house developed RTTR model based on DTS temperature revealed the predictive power of the Marlinks RC-ladder model. The utilization of the FEM-based calculation proved to be a strong indicator for RTTR accuracy. Notably, the experiment demonstrated that the Marlinks model outperformed the industry-standard method in terms of accuracy and applicability, primarily due to its better alignment with the cable’s intricate geometry and fiber temperature variations.

Conclusion: Revolutionizing Real-Time Thermal Rating for Subsea Cables

Through experimental validation, Marlinks’ innovative RC-ladder model was confirmed to be highly predictive for real-time thermal rating (RTTR). The successful correlation between measured and model-predicted core temperatures showcased the effectiveness of the FEM-based approach. Importantly, this case study revealed that a robust RTTR model can enable cables to handle significantly higher currents than traditionally prescribed by industry standards. By addressing the complex challenges of submarine power cables’ temperature relations, this contributes to enhancing cable performance and efficiency.

Want to learn more?

Are you responsible for the health of submarine cables? Let’s have a chat at sales@marlinks.com and we will be happy to help you.