The Crucial Role of Marlinks' Thermal Models for Subsea Power Cables.

In the offshore wind energy sector, subsea power cables play a crucial role in efficiently transmitting electricity from offshore turbines to the shore. Recognizing their importance, continuous monitoring is essential to ensure the operations of these critical assets. At Marlinks, our approach is straightforward and effective. We use thermal models to precisely map the cable’s temperature distribution along its entire length.

This detailed temperature information is instrumental in various applications, including burial status calculation, exposure detection, and hot spot alerting. Our approach involves working with two main types of models: Finite Element Analysis (FEM) for engineering office calculations and validation, and Thermal Ladder Models for real-time operational applications. This ensures accurate and practical insights into subsea cable dynamics, allowing for informed decision-making and optimal performance.

The Marlinks Model provides a detailed temperature distribution of subsea cables, starting from measurements provided by a Distributed Temperature Sensing (DTS) device. With the aid of our reduced thermal model, we calculate and provide essential quantities for our monitoring services.

Heat transfer in subsea cables

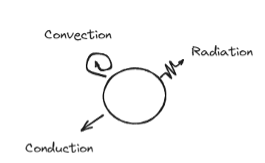

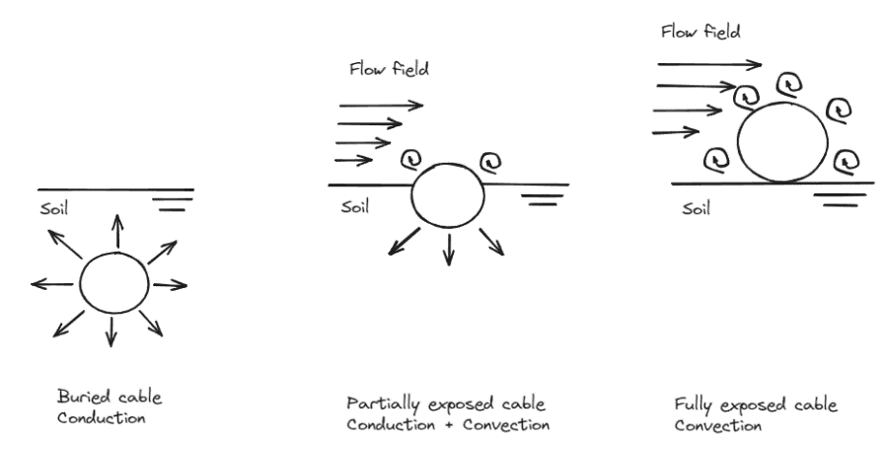

Distributed measurements offer valuable cable status information. However, the cable’s thermal distribution is crucial for deriving additional information, where thermal modeling plays a pivotal role. These models need to properly incorporate the following heat transfer processes: radiation, conduction, and convection.

- Radiation plays a negligible role in the heat balance of buried submarine cables. However, radiation must be considered in specific cases for cable segments above the water level.

- If a cable is buried, it is usually considered that the soil pores are small enough that convective cells cannot establish and thus the thermal behaviour of the cable is dominated by conductive heat transfer.

- If the cable is exposed to water, convective heat transfer becomes dominant: convection is a much more efficient conveyor of heat than conduction.

Thermal models

We navigate this intricate terrain with two models. The Finite Element Model (FEM) unveils the detailed internal thermal behavior of cables, used for validation purposes. The Marlinks’ Thermal Ladder Model seamlessly complements FEM by focusing on key elements such as the conductor, metallic sheath, armour, and interstitial optic fiber.

Finite Element Model (FEM):

- Requires settings for cable geometry, boundary conditions (steady state or transient), material properties, and initial conditions.

- Offers a detailed view by discretizing the cable’s geometry into tiny elements. However, its high computational cost limits its use in an operational context.

Thermal Ladder Model:

- Assimilates the thermal behavior of the cable into an electrical circuit, providing accurate under specific conditions.

- Computationally efficient for use in real-time applications and thereby well suited for modelling long cables.

The Marlinks Thermal Model stands out as the most suitable solution for modelling long cables, offering a fast calculation with sufficient resolution to provide accurate results. While both models are instrumental, the ladder model’s efficiency makes it a preferred choice for gaining insights into extensive cable systems in an operational context.

Want to know more?

Explore additional information about Marlinks’ subsea cable monitoring services with fiber optic technology or want to discuss your specific needs? Contact us via email at sales@marlinks.com or give us a call at +32 485 07 99 30. Our team is ready to assist you!